Kinetic Metallization: Background

Background: Metal Deposition Processes

Kinetic Metallization™ (KM) is not the only method for creating metal coatings, but it does set itself apart from competing methods. First, it is important to understand what other technologies exist and their strengths and limitations are.

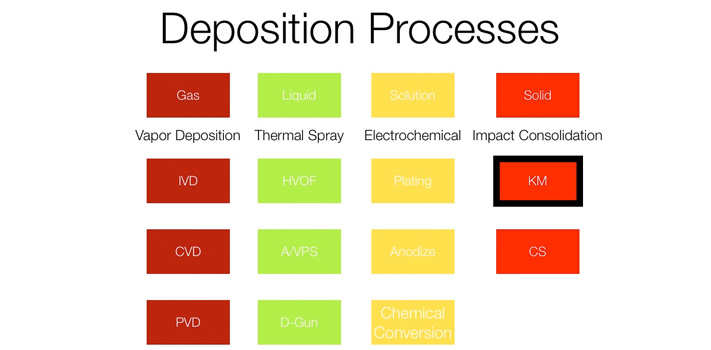

All metal deposition techniques fall into one of four categories: vapor deposition, electrochemical deposition, thermal deposition or impact consolidation. Each family has its own set of inherent advantages and drawbacks.

Vapor deposition processes are deposited in a vacuum chamber. The feedstock is delivered as a vapor and is ideally deposited in an atom-by-atom basis. The deposition is not subject to chemical reaction, unless intended like in CVD, because air is not present in the chamber. The morphology, and often the lattice structure of the deposition is more functionally related to those of the substrate than to those of the feedstock. While these processes can be used to coat non-line-of-sight regions, it requires additional setup to produce even coatings. Deposition rates are slow and the limiting thickness is generally a few microns. Another drawback is that these coatings cannot be repaired in the field.

Electrochemical methods require the substrate to be immersed in a bath where an imposed electrical current or galvanic driven current is used to reduce metallic ions on the surface of the substrate. Like the gas-phase processes, deposition is atom-by-atom and there are thickness and deposition rate limitations. Many of these methods, including hard chrome, produce environmentally compromising byproducts. Electroplated coatings are also subject to micro-cracking which decreases the quality and corrosion resistance. The solution-based processes are suited for non-line-of-site deposition, and these coatings can be repaired using brush electroplating methods, however this increases the operators’ exposure to the harmful byproducts and the electrical current.

Thermal deposition methods incorporate a variety of methods, but they all rely on melting the metal that is being deposited. KM can be used to deposit materials traditionally applied using thermal spray methods including HVOF, HVAF, plasma sprays and d-gun technologies including tungsten carbide and MCrAlY coatings. Thermal spray feedstock is often quite different than KM versions of the same base materials, and generally these differences are due to the need to melt the particles during thermal spray. For example, thermal spray uses a larger particle size than KM to resist chemical reactions (e.g., oxidation, decarburization) with the air that surrounds the molten spray plume. An additional concern at these high temperatures is the de-alloying of the feedstock during deposition. Thermal spray processes are often capable of depositing pure ceramic feedstock as well as metals and alloys. Since these processes occurs at temperatures high enough to melt the feedstock material the substrate material is also subjected to high temperatures. This limits both the size and the materials of components that can be coated with thermal spray.

Impact consolidation methods are the only way of depositing metals without a phase change. They rely on mechanical energy and the ductility of the feedstock to deposit material. Since there is no phase change all particles in the coating have the same thermo-mechanical history which leads to uniform properties of the coating. The two main methods of performing impact consolidation are Kinetic Metallization™ and cold spray. Both processes accelerate particles to supersonic speeds but Inovati’s patented friction compensated sonic nozzle design sets KM apart. The sonic nozzle design means that KM is able to achieve sonic particle velocities at much lower pressures and using less than one-tenth the gas. Inovati’s patented powder feeder design reliably feeds a wide variety of feedstocks. These technologies are why Kinetic Metallization™ is the only impact consolidation deposition method that can deposit tungsten carbide and niobium based coatings. KM coatings can also be repaired in the field using the KM-MCS system and have been deposited to thicknesses greater than one inch.