Kinetic Metallization: IVD Field Repair

Al-Trans® Characteristics

High Corrosion Resistance

High Conductivity

High Adhesion Strength

Metallurgical Bonds

Fully Dense

Self-Healing Abrasion Resistance

Al-Trans® vs. Aluminum IVD

Field Repairable

No Hydrogen Embrittlement

Self-Healing Abrasion Resistance

Reduced Oxidation

Reduced Thermal Distortion

Increased Corrosion Resistance

Lower Cost

IVD Aluminum Repairs with Al-Trans®

Aluminum Ion Vapor Deposition (IVD) is currently the accepted replacement of cadmium corrosion protective coatings. Unfortunately, the IVD process cannot be repaired in the field. Thus, the Navy Air Warfare Center at Patuxent River, MD funded Inovati with a Small Business Innovative Research (SBIR) project to develop environmentally acceptable methods of spray depositing aluminum coatings for repairing aluminum IVD on military aircraft.

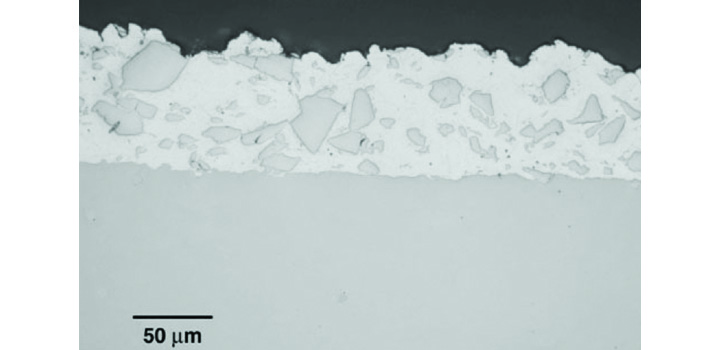

Inovati has developed an aluminum based composite powder, Al-Trans® 10-20-50, with exceptional corrosion protection. Our portable handheld spray gun was developed to apply this coating.

Al-Trans® 10-20-50, and the KM process avoid the expensive, elaborate equipment required for IVD, molten salt bath plating and Alumiplate processes. Al-Trans® 10-20-50, can easily be used as the primary coating on critical parts. It has a high adhesion strength due to a metallurgical bond between the coating and the substrate. Additionally, the coating’s near zero porosity gives it the corrosion resistance to pass more than 5000 hours of salt spray and SO2 salt spray per ASTM D1654-92.