Kinetic Metallization: Conformal Antenna and Electronics

KM Benefits vs. HVOF

No Grit Blasting Required

Precise Coatings

Better Conductivity (Reduced Oxide)

High Target Efficiency

KM Antenna & RF Capabilities

Metallic Conductors

Direct Write Capability

Complex Surface Morphologies

Tunable dielectrics

Multiferroic Materials

Application Areas

Airborne Satcom

Missiles & Munition Antenna

EMI Shielding

RF Waveguide Brazing

RF Electrical Packaging

Radar Systems

Conformal Antenna Aperstructures

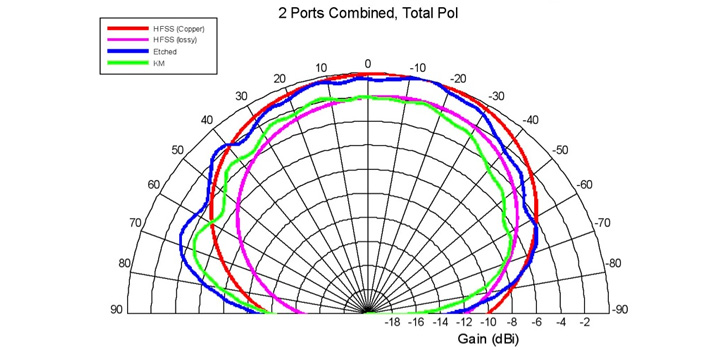

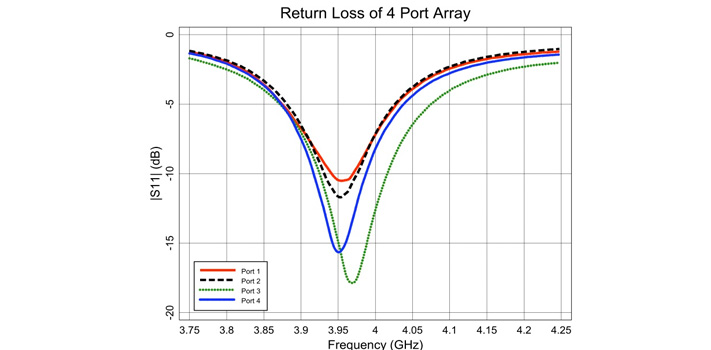

SatCom systems for aircraft and spacecraft uplink/downlink applications require that antenna array elements possess high bandwidth, efficiency, and gain. Aerodynamic drag of protruding SatCom antennae can be eliminated by directly mounting large patch antenna arrays directly on the surface of load bearing structures. Kinetic Metallization™ (KM) is a superb solution for applying these antennae.

Inovati has developed direct write techniques for applying antenna conductor elements and traces to doubly curved dielectric surfaces using Kinetic Metallization. Specially designed KM nozzles make it possible to deposit copper and silver traces with line-widths of < 1-mm. Inovati also developed multi-axis robot translation of the KM Gun to facilitate repeatable and uniform deposition of conductor elements and traces onto doubly curved polymeric and ceramic dielectrics for conformal antenna manufacturing.

The KM process can also direct write polymer-based dielectric composites with tunable dielectric properties. These materials can be deposited with spatially varying dielectric constants to permit RF phase shifting and antenna gain compensation.