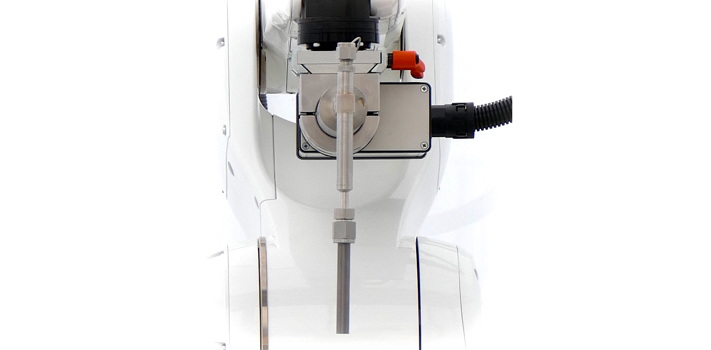

Kinetic Metallization: Nozzle Design

What Makes The KM Nozzle So Special?

Impact consolidation processes (KM and cold spray) rely solely on kinetic energy to achieve the necessary deformation of the feedstock particles to create coatings and freestanding shapes. For a particle of given mass, the sole means of increasing particle kinetic energy is to increase particle velocity. Inovati learned early on that supersonic gas velocity is not desirable for achieving high particle velocity at low cost.

The supersonic approach (cold spray) is to accelerate gas to the highest possible velocity in an attempt to accelerate particles to the highest possible velocity. However, once past the nozzle throat, a supersonic gas has very low density and low pressure, which eliminates its ability to push particles effectively. Also, once a gas exceeds Mach 1, it must eventually slow below supersonic velocity. This transition produces shockwave phenomena, which decreases particle velocity, deposition efficiency, and coating quality.

The sonic approach (KM) is to accelerate gas to just below sonic velocity so that the gas density after the nozzle's throat remains essentially equal to that at the nozzle throat. The combination of gas density and gas velocity produces a higher aerodynamic cross-section for a longer period of time. The increased dwell time and acceleration efficiency results in higher velocity particles than supersonic nozzle designs. This fundamental difference in Inovati’s design allows KM equipment to operate using as little as 1/10th the pressure (much lower operating costs) of competing processes while achieving superior results and being able to deposit a wider range of materials.