Kinetic Metallization: Gas Blending

Gas Blending

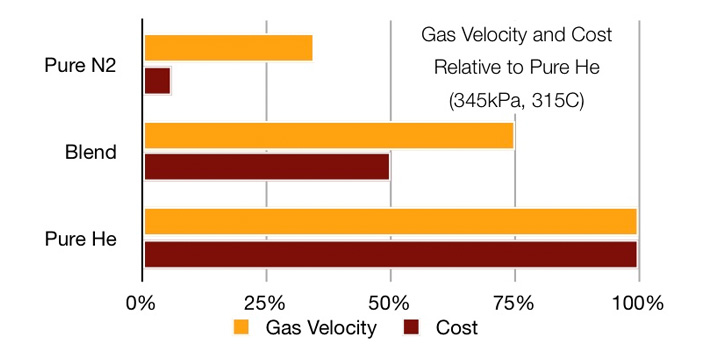

Because Kinetic Metallization™ accelerates particles to sonic velocities, the gas used to accelerate the feedstock particles is important because the speed of sound is different in each gas. Kinetic Metallization™ uses an inert gas, typically Helium (He) or Nitrogen (N2), to accelerate the feedstock particles. Helium is the preferred gas, especially for high strength and ceramic rich feedstocks, because the sonic velocity of Helium is three-times that of Nitrogen at the same temperature. This is because higher velocity particles deform more when they are deposited and create a higher quality coating. Unfortunately, Helium is more expensive than Nitrogen.

In order to balance the higher price and sonic velocity of Helium with the lower cost and sonic velocity of Nitrogen, Inovati designed KM equipment with the capability to blend both gasses during operation. (This is especially beneficial in Japan, where Helium is approximately six-times more expensive than Nitrogen) When using blended Helium and Nitrogen, KM equipment accelerates the feedstock particles to 75% of the sonic velocity of Helium but cuts the operating costs in half. Also, Inovati’s unique gas manifold and valve system makes changing from mixed gas to single gas operation as simple as turning a dial.