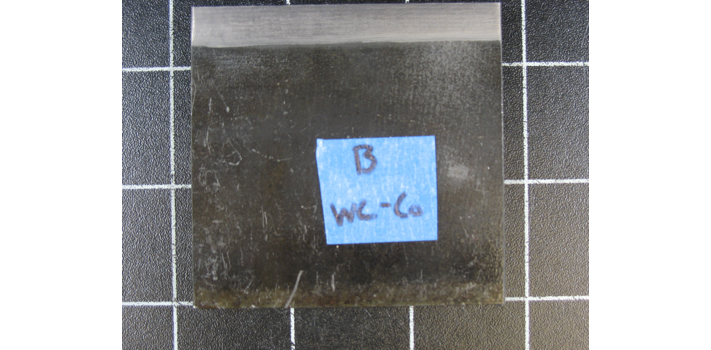

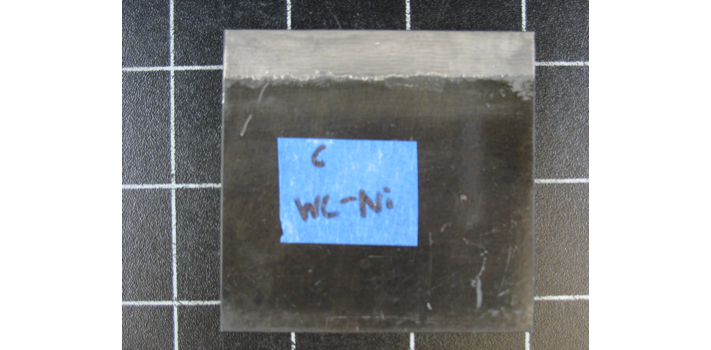

Kinetic Metallization: Cutting Blade Coatings

KM WC Characteristics

Tunable Hardness (700-1500HV)

Fully Dense

No Decarburization

Excellent Adhesion Strength

Corrosion Resistant

Wear Resistant

Temperature Resistant

High Target Efficiency

Application Areas

Temperature Sensitive Materials

Edge Preservation

Wear Resistance

Fatigue Resistance

Corrosion Resistance

Kinetic Metallization Blade Coatings

Cutting blades regularly suffer from wear, scratches, and other abrasions due to the nature of their use. To alleviate this problem, Inovati has utilized its Kinetic Metallization™️ technology to deposit wear resistant WC-based coatings on blades to protect the material. The low temperature nature of KM is suitable for deposition on heat-treated steel, giving blades 25% longer life. KM HF coatings can be applied to anything from industrial guillotine blades to lawn mower or razor blades. Thermal spray techniques like HVOF and plasma spray ruin heat treated steels, and have poor deposition efficiency on small blades. Hard chroming blades is slow and provides inferior hardness and operator safety as compared to KM.