Kinetic Metallization: F/A-18 Brake Carrier

Al-Trans® Characteristics

High Corrosion Resistance

High Conductivity

Self-Healing Abrasion Resistance

Fully Dense

High Adhesion Strength

Good Corrosion Resistance

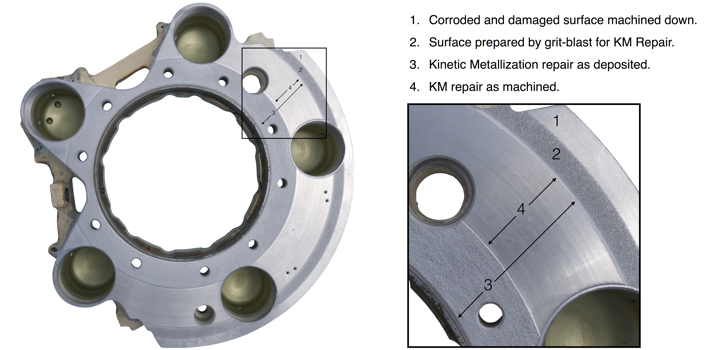

NAVAIR F/A-18 Brake Carrier Repair

The brake carier in the picture abovehas been partially sprayed to showcase the stages of the KM dimensional repair.

Region 1 is the parent material after the corroded and damaged surfaces were machined away

Region 2 is shows the surface after grit-blasting. This is an optional step that enhances the adhesion of the repair

Region 3 shows the appearance of the KM coating after deposition

Region 4 shows the final appearance of the KM coating after machining

As you can see the final appearance of the repair is indistinguishable from the original part. However, the KM repair is more corrosion resistant than the parent material. This means that the replacement part will have a greater lifespan than the original, reducing downtime and maintenance costs.

KM repairs are estimated to save the Navy $2.2 Million a year, not to mention drastically reducing the lead-time for critical replacement parts. The proven success of KM repairs on these parts has prompted NAVAIR purchase a series of KM-PCS units and to fund the development of other part repairs. Contact Inovati today to find out what Kinetic Metallization can do for you.