Kinetic Metallization: Braze Joint Preparations

KM vs. Standard Brazing

Increased Bond Strength

Fully Dense

No Heat Treatment

No Oxidation of Braze Joint

Uniform and Repeatable Application

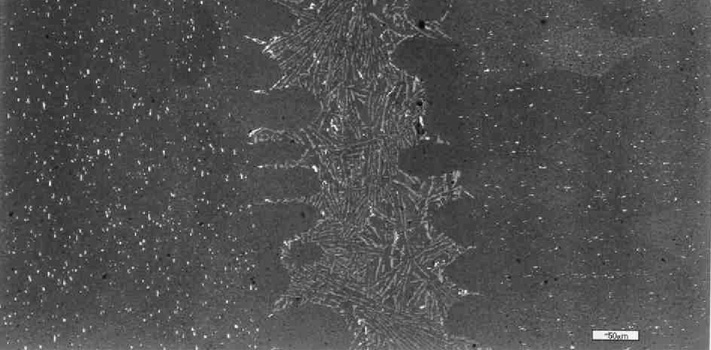

Reduced Diffusion of Undesirables

Shorter Production Time

Increased Efficiency

Braze Joint Preparations

Brazing methods are dependent on flow by capillary action or on cements or pastes to distribute the braze alloy throughout the joint. Capillary transport methods require precise spacing and often use more braze material to insure that the joint is filled. Cements and pastes require temporary binders that are supposed to bake off before the braze material melts, this requires longer heating times to ensure that the binders evaporate and do not interfere with the braze. Kinetic Metallization™ circumvents theses concerns by directly applying the braze alloy to the braze joint surface, without the need for temporary binders.

The low temperature and high particle velocities of KM are excellent for applying a uniform layer of braze alloy to parts before brazing and allows for excellent control over the amount of braze being applied. Additionally, KM application of braze alloys is proven to decrease the diffusion of undesirable components like Si into the substrate. All these factors lead to a superior, repeatable, uniform braze with a shorter processing time and minimal waste.