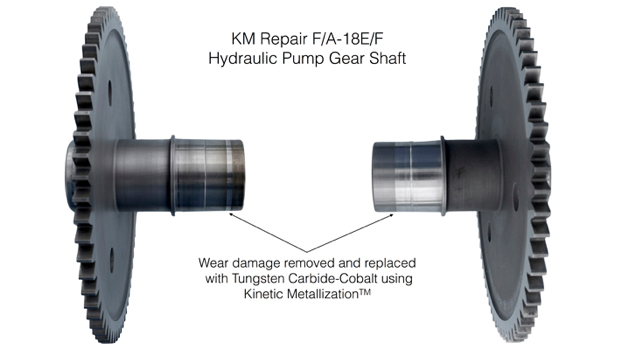

Kinetic Metallization: F/A-18 Hydraulic Pump Gearshaft

KM WC-Co Characteristics

Tunable Hardness (700-1500 HVC)

Fully Dense

High Adhesion Strength

Good Corrosion Resistance

No Decarburization

Field Repairable

Unaffected by extreme Temperature

KM WC-Co vs. Hard Chrome

Higher Microhardness

Smaller, Safer Equipment

Environmentally Safe

Enhanced Worker Safety

Lower Cost

Faster for Small to Medium Parts

Application Areas

Hard Chrome Replacement

Temperature Sensitive Materials

Small Parts

Wear Resistance

Fatigue Resistance

Corrosion Protection

NAVAIR F/A-18 Gearshaft Repair

Kinetic Metallization™ (KM) has proven to be the superior repair for dimensional restoration and hardfacing of high value and temperature sensitive parts for NAVAIR. The repair of hydraulic gear shafts is one of the many applications for KM. The hydraulic gear shaft is a part of the airframe mounted accessory drive and experiences wear at a sealing interface. This occurs because the part requires the inside of the shaft to be soft which limits the hardness (and wear resistance) that can be achieved on the outside of the shaft using conventional processing. In the past these shafts were repaired using electrolytic hard chrome. However, environmental considerations and the fact that the parts would wear out again prompted the search for an alternative repair.

Inovati developed a repair with KM HF 10-10 for NAVAIR. Two parts were repaired by Inovati and sent to NAVAIR for evaluation. One of the parts was cross sectioned and examined. The repair was found to be sufficiently hard, uniform, fully dense, and tightly bound to the substrate with no signs of separation, voids, or cracks. Additionally, the evaluation showed that the microstructure of the base material was preserved. Once it had been determined that the repair met the basic requirements, it was time to determine if the repair would improve the lifespan of the gears.

| Part | Original surface roughness | hours tested | final surface roughness |

|---|---|---|---|

| KM repaired | 2-3 μin Ra | 61 | 16-17 μin Ra |

| OEM | 18-20 | 22 | >200 (off scale) |

| Hard Chrome | 4-5 | 21 | >200 (off scale) |

To evaluate this, the second part was subjected to an accelerated wear test and compared against the OEM part and a part that had been repaired with hard chrome. The test involved running the gear in its application environment and replacing the lubricant with a mixture of aluminum oxide grit and oil. The OEM gear lasted 22 hours before it failed due to excessive wear, while the hard chrome repair lasted 21 hours before failing. The KM repaired gear was tested for 61 hours before the test was stopped. Even after 61 hours the KM repair was unscratched. In fact, it was later found that abrasive was breaking down instead of the coating.

Now that the KM repair is proven to surpass NAVAIR’s requirements, it is the repair of choice for many applications. That is why NAVAIR has purchased a series of Kinetic Metallization Production Coating Systems (KM-PCS) and continues to fund the development of other part repairs. It is estimated that Kinetic Metallization is saving the Navy $2.2 Million a year, while drastically reducing the lead-time for critical replacement parts.